Centrifugal Compressor

Your shopping cart is empty!

Product Description

Centrifugal Air Compressor Freatures and Advantages:

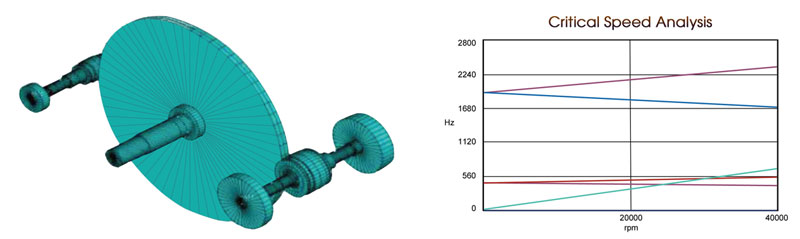

01 Rotor dynamic analysis

Rotor system critical speed analysis is the theory of safety operation of compressor.

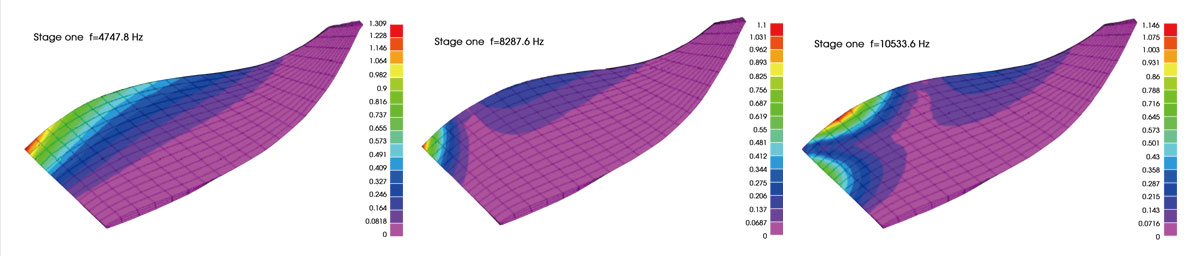

02 Rotor modal analysis

Analyze various vibration modes of impeller under high speed rotating state, and adjust relevant design parameters to avoid resonance, ensure stable operation and work of the compressor.

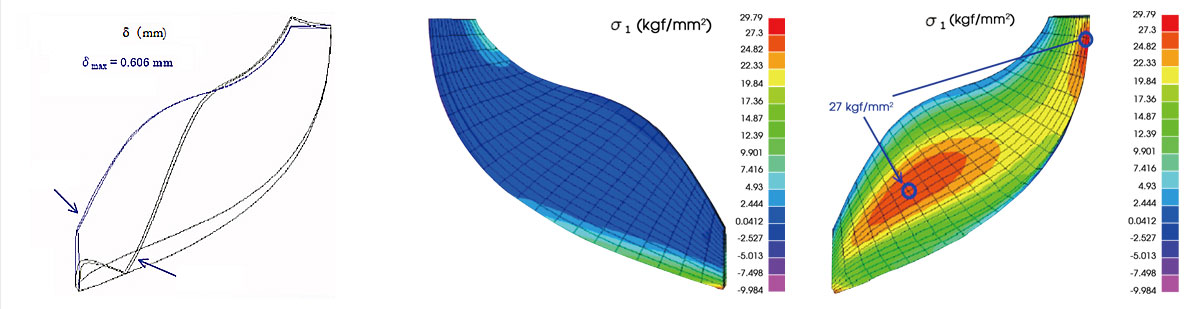

03 Stress and strain analysis of impeller

Use the professional designing tool, the impeller strength analysis, and the selection of different materials and structures, the impeller is safe loaded which ensure the long life and stable operation of itself.

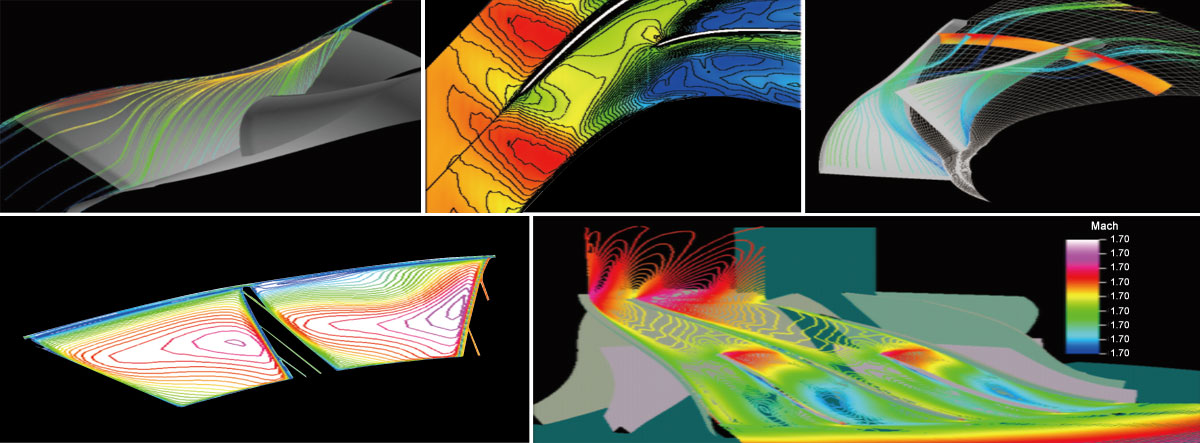

04 The aerodynamic design

Through CFD calculation and analysis of the basic model, the shape and collocation of blade, diffuser and scroll are optimized, and the aerodynamic design is constantly improved to achieve higher efficiency and wider turndown range.

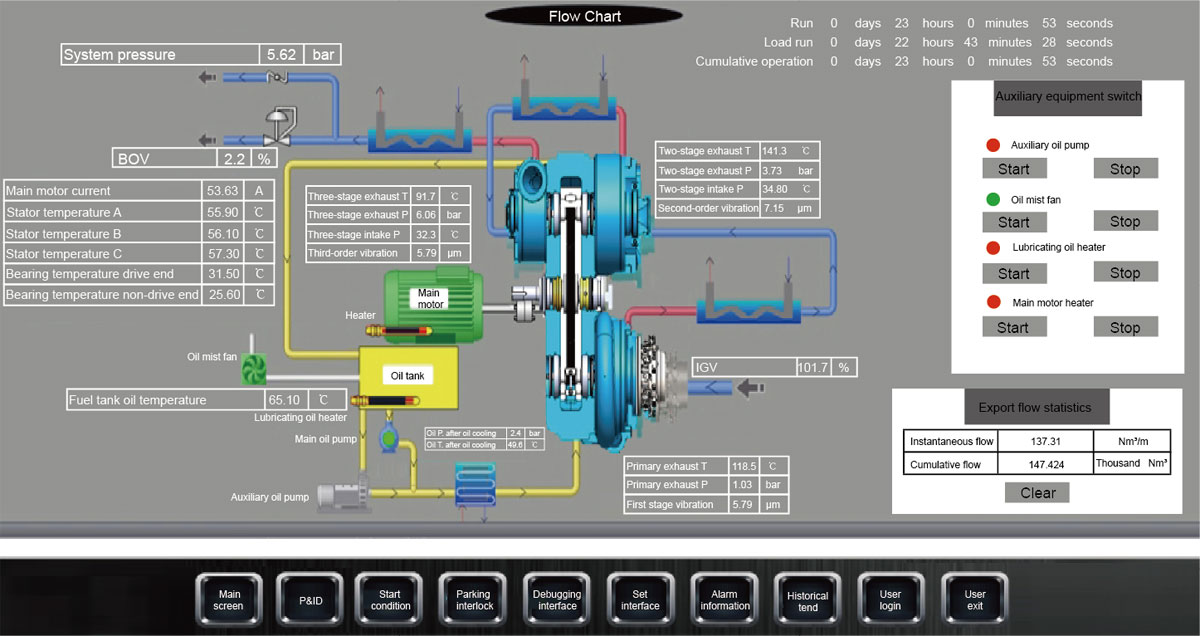

Advanced control system

- Standard 12〞touch screen, all parameters of the compressor can be viewed on it, easy to operate;

- Standard Siemens PLC, automatic dual mode + constant voltage control mode can be switched locally and remotely to ensure safe and stable operation;

- Automatic remind when the faults occur or maintenance is needed;

- Historical data can be viewed locally and remotely.

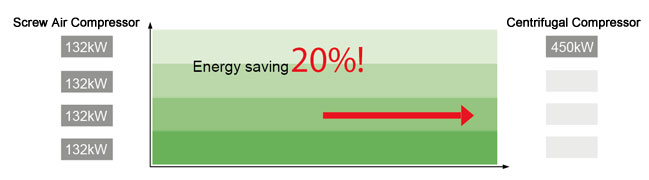

Energy saving and emission reduction

Generally, the larger volume, the higher efficiency. One centrifuge can save about 20% energy when replacing several small screws.

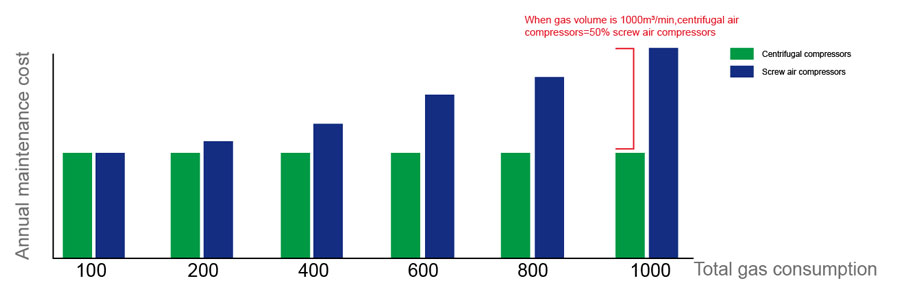

Use centrifuge to replace many screw machines, save maintenance cost & time and site area.

| Model | Working Pressure | Capacity(FAD) | Motor Power | Dimensions(mm) | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| bar(e) | psig | m³/min | cfm | kW | Hp | L | W | H | Kg | |

| DAC50 | 0.6-9 | 8.7-130.5 | 50-70 | 1766.38-2472.93 | 300-450 | 400-600 | 3280 | 1850 | 2200 | 6300 |

| DAC100 | 0.6-9 | 8.7-130.5 | 70-130 | 2472.93-4592.59 | 400-640 | 530-900 | 3800 | 2000 | 2250 | 8160 |

| DAC150 | 0.6-12 | 8.7-174 | 120-160 | 4239.42-5652.42 | 630-800 | 840-1200 | 4200 | 2150 | 2350 | 11500 |

| DAC200 | 0.6-16 | 8.7-232 | 160-230 | 5652.42-8125.36 | 760-1120 | 1010-1750 | 4200 | 2150 | 2350 | 12000 |

| DAC300 | 0.6-16 | 8.7-232 | 230-330 | 8125.36-11658.12 | 980-1600 | 1320-2150 | 4600 | 2200 | 2500 | 17200 |

| DAC400 | 0.6-16 | 8.7-232 | 330-440 | 11658.12-15544.16 | 1380-2250 | 1840-3000 | 5300 | 2300 | 2970 | 21500 |

| DAC500 | 0.6-25 | 8.7-362.5 | 350-580 | 12364.67-20490.03 | 1800-2850 | 2400-3800 | 6000 | 4500 | 3500 | 40000 |

| DAC700 | 0.6-25 | 8.7-362.5 | 530-900 | 18723.65-31794.87 | 2700-4500 | 3600-6000 | 8500 | 4200 | 4200 | 45000 |

| DAC900 | 0.6-25 | 8.7-362.5 | 850-1500 | 30028.49-52991.45 | 4200-9000 | 5600-12100 | 12000 | 5000 | 5300 | 65000 |

| Model | Working Pressure | Capacity(FAD) | Motor Power | Dimensions(mm) | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| bar(e) | psig | m³/min | cfm | kW | Hp | L | W | H | Kg | |

| DAC50 | 0.6-9 | 8.7-130.5 | 50-70 | 1766.38-2472.93 | 300-450 | 400-600 | 3280 | 1850 | 2200 | 6300 |

| DAC100 | 0.6-9 | 8.7-130.5 | 70-130 | 2472.93-4592.59 | 400-640 | 530-900 | 3800 | 2000 | 2250 | 8160 |

| DAC150 | 0.6-12 | 8.7-174 | 120-160 | 4239.42-5652.42 | 630-800 | 840-1200 | 4200 | 2150 | 2350 | 11500 |

| DAC200 | 0.6-16 | 8.7-232 | 160-230 | 5652.42-8125.36 | 760-1120 | 1010-1750 | 4200 | 2150 | 2350 | 12000 |

| DAC300 | 0.6-16 | 8.7-232 | 230-330 | 8125.36-11658.12 | 980-1600 | 1320-2150 | 4600 | 2200 | 2500 | 17200 |

| DAC400 | 0.6-16 | 8.7-232 | 330-440 | 11658.12-15544.16 | 1380-2250 | 1840-3000 | 5300 | 2300 | 2970 | 21500 |

| DAC500 | 0.6-25 | 8.7-362.5 | 350-580 | 12364.67-20490.03 | 1800-2850 | 2400-3800 | 6000 | 4500 | 3500 | 40000 |

| DAC700 | 0.6-25 | 8.7-362.5 | 530-900 | 18723.65-31794.87 | 2700-4500 | 3600-6000 | 8500 | 4200 | 4200 | 45000 |

| DAC900 | 0.6-25 | 8.7-362.5 | 850-1500 | 30028.49-52991.45 | 4200-9000 | 5600-12100 | 12000 | 5000 | 5300 | 65000 |